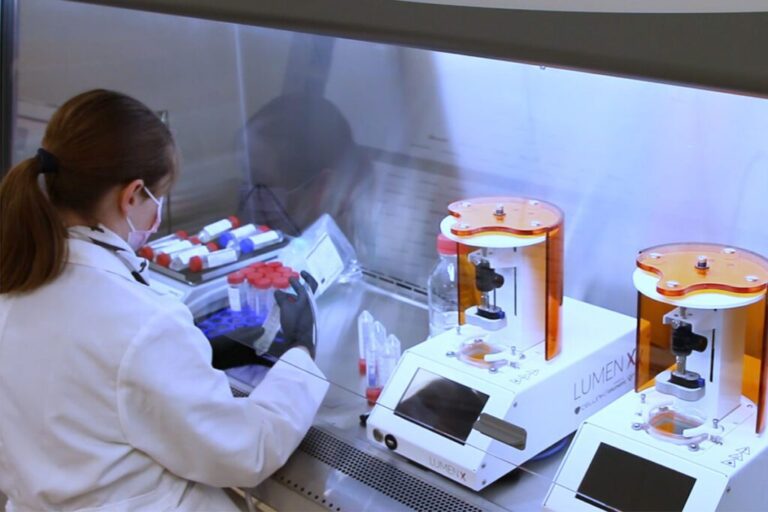

The BIO X 3D Bioprinter is helping accelerate the healing of diabetic foot ulcers (DFU) with 3D bioprinted patches that enable sustained release of antibiotics directly to the wound area. For the enterprising Lamprou Lab in Belfast, this breakthrough is more than academic; you could say it is also personal.

3D bioprinted patches prevent bacterial infections that interfere with proper wound healing in diabetic foot ulcer patients

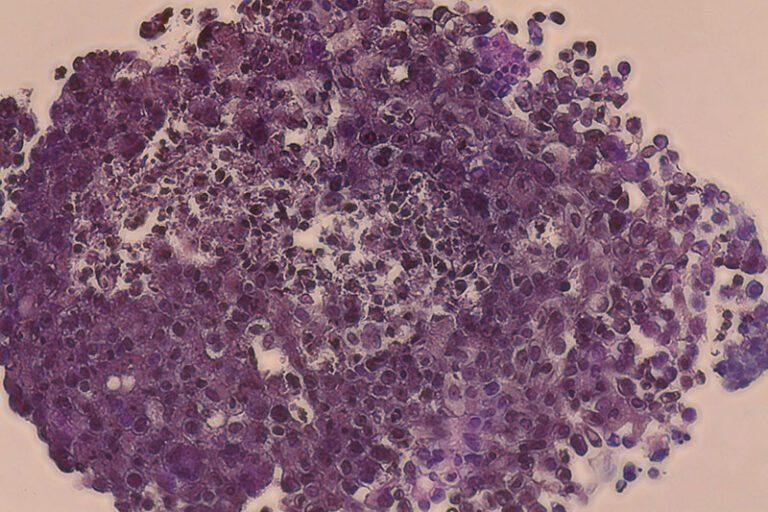

More than a third of diabetics develop DFUs in their lifetime, and nearly half of those wounds get infected, with Staphylococcus aureus, Pseudomonas and Escherichia coli being the most common pathogens. These infections contribute to poor wound-healing outcomes for diabetic patients and could even lead to lower-limb amputations. “I wanted to make DFU treatment less painful and time-consuming,” says the professor of pharmacy.

The FDA-approved polycaprolactone polymer proved to be the ideal biodegradable biomaterial for the wound-healing patch

The paper in Drug Delivery and Translational Research details how the BIO X bioprinted a mix of the biodegradable polymer polycaprolactone (PCL), which has been previously cleared by the FDA for use in other biomedical devices, with the broad-spectrum fluoroquinolone antibiotic levofloxacin to produce the wound-healing scaffolds. “These thermoplastic hydrogels are excellent for wound treatment given their biocompatibility, slow rate of degradation and good mechanical properties, such as flexibility to move freely,” explains Professor Lamprou.

At the patient level, Lamprou Lab’s antibiotic delivery patches solve several concerns. For example, the higher doses needed for oral administration of antibiotics can induce toxicity, while intravenous administration can be invasive, even requiring hospitalization. Not to mention reducing the proliferation of antibiotic-resistant bacterial strains attributed to the overuse of system-wide antibiotics. The slow degradation of PCL approach, however, facilitates the sustained, localized delivery of antibiotics at the wound site, provides a robust support structure as the skin repairs itself, and doctors can easily dress a wound in their office with no need for costly hospitalization.

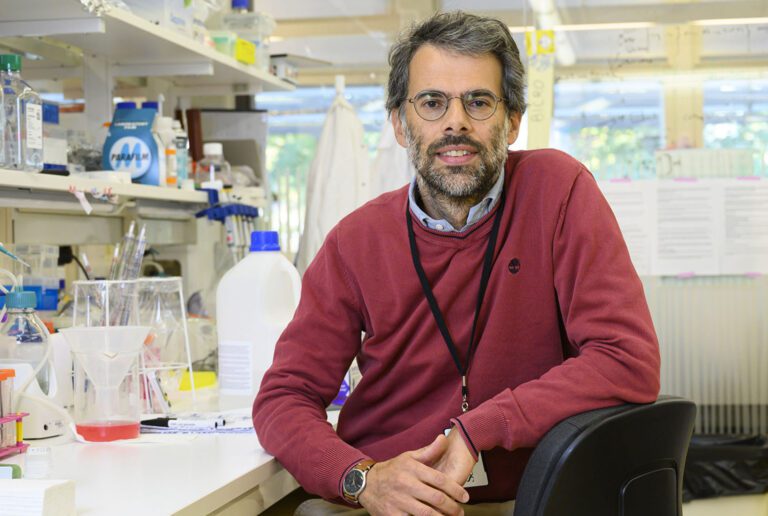

Professor Dimitrios Lamprou, the chair of Biofabrication and Advanced Manufacturing at the School of Pharmacy, Queen’s University Belfast, who may have been destined to work on this novel 3D bioprinted wound-healing patch.