Printing vascularized skin

“…we could potentially even think of using this as a therapy for burn victims.”

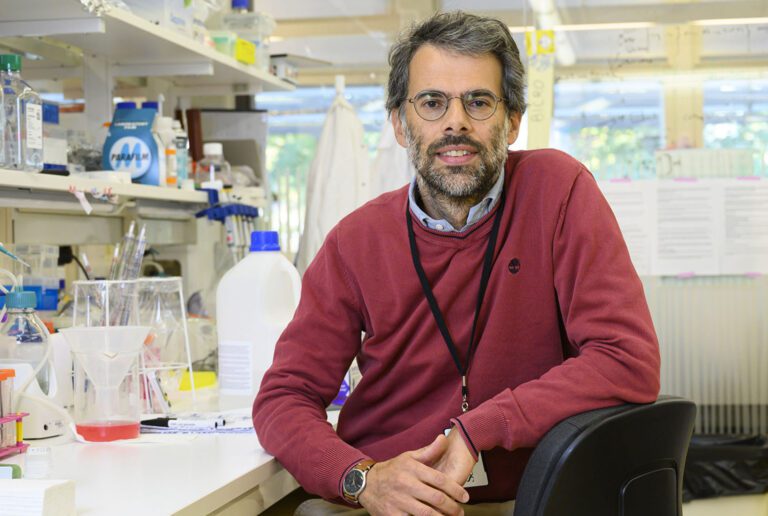

Pankaj Karande

Associate Professor

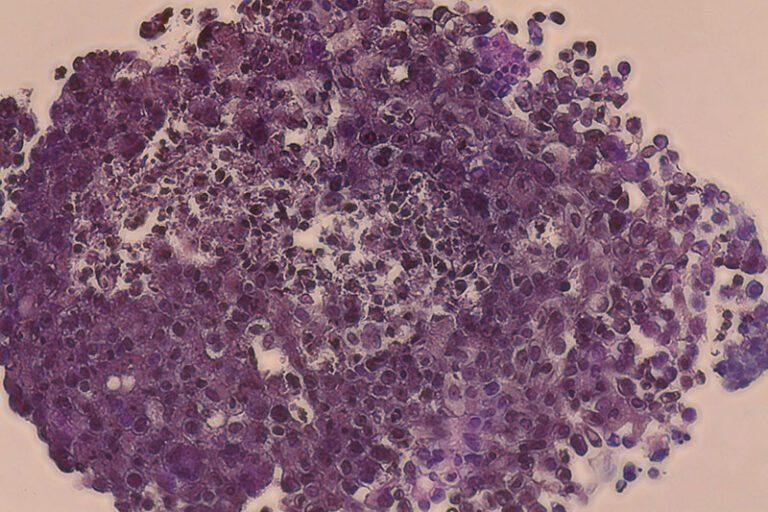

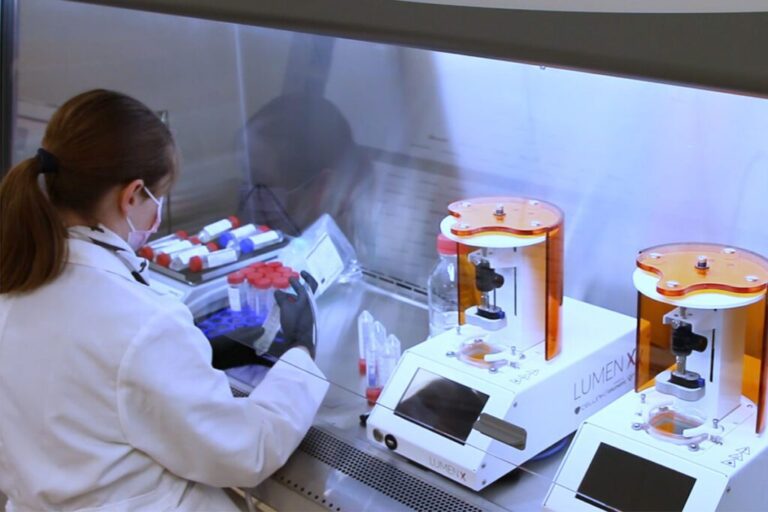

Karande and his team have developed a bioink made up of human endothelial cells, human pericyte cells and animal collagen. They used the CELLINK BIO X bioprinter and Temperature Controlled Printhead to ensure that these constructs could be printed.

This combination of key elements enabled the cells to start communicating and more importantly begin forming a biologically relevant vascular structure within the span of a few weeks. Once blood vessels formed, nutrients and waste could be exchanged to keep the graft alive. The groups significant development highlights the vast potential of 3D bioprinting in precision medicine, where solutions can be tailored to specific situations.