Developing treatments for knee injuries

As it stands today, one out of four Swedes over the age of 45 suffer from some degree of osteoarthritis. Dr. Simonsson and her group began their research to develop a solution for this widespread problem by developing mini-knees in test tubes, culturing iPSC’s and having them differentiate into cartilage cells. These mini-knees helped pave the way to understand disease mechanisms and what causes the cartilage to decay.

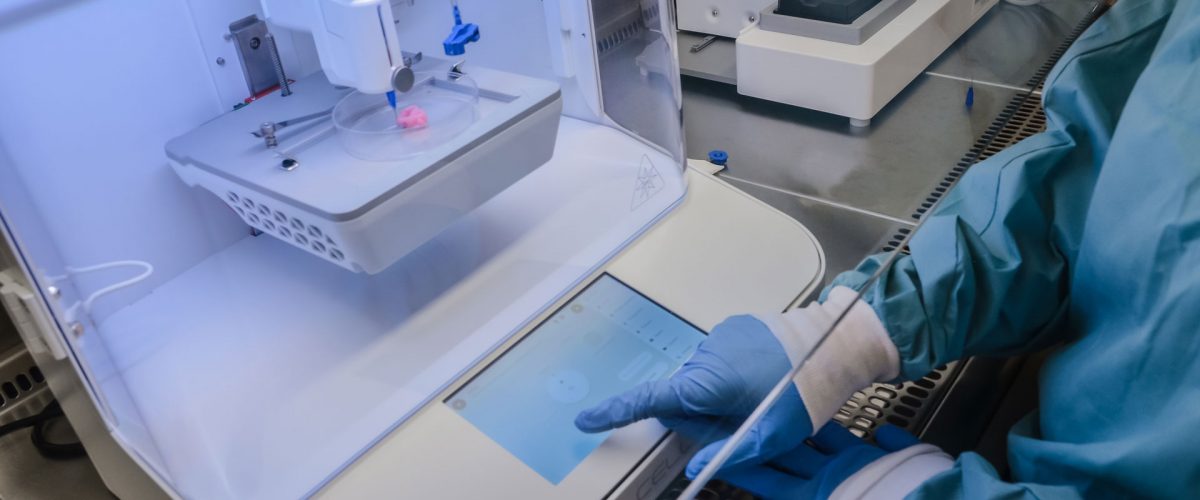

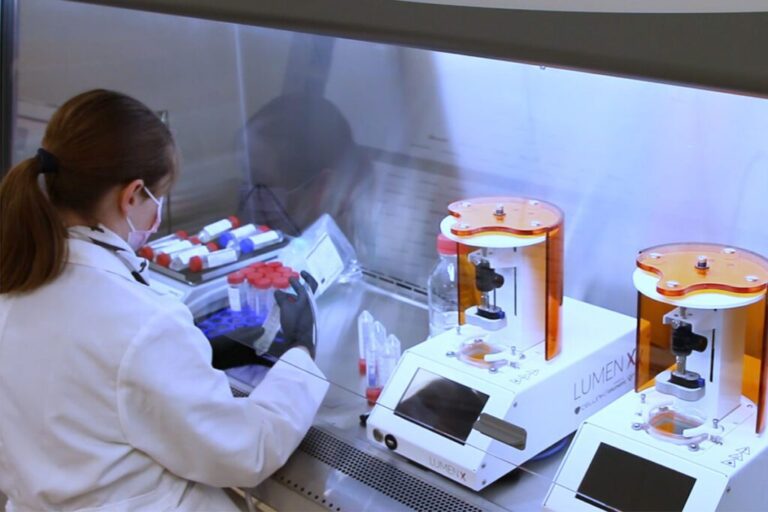

Bioprinting personalized iPS cell-laden implants for a perfect fit

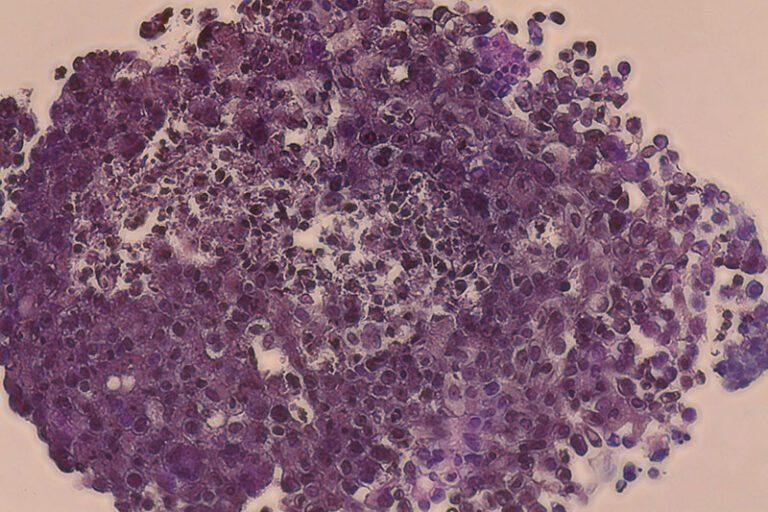

Armed with an understanding of what causes stem cells to differentiate into cartilage, Dr. Simonsson and her team unlocked a new degree of personalization by taking patient scans and using the BIO X to develop patient specific constructs. These iPSC laden constructs were printed using a combination Nanocellulose and alginate similar to CELLINK’s bioink. Optimizing the bioink allowed for a high degree of fidelity for the print, but more importantly, safety during the printing process, which in turn ensured high cell viability and high probability of differentiation. This process entailed a robust construct with ECM proteins like Collagen Type II and GAGS being developed in abundance. This bioprinted cartilage when compared to in vivo cartilage was indiscernible, even by trained surgical eyes.

Taking on demand cartilage from basic research to clinical therapies

Having successfully demonstrated that on demand cartilage can be bioprinted, the team now turns their eyes to translating this research into clinical therapies. To do so, the team is faced with a number of challenges. One such challenge is finding a suitable material that possesses the same rheological properties as their bioink but has a structure even closer to humans and also enables a simpler path through the regulatory obstacles that must be navigated as research is turned into treatments.